[ad_1]

Last updated on

Dive into the world of concrete recycling because it combines innovation, environmental practicality, and profit potential in a surprisingly seamless way.

Key takeaways:

- Concrete recycling reduces gravel mining and air pollution.

- Recycling concrete conserves landfill space and decreases costs.

- Find recycling facilities through online searches, local companies, and databases.

- The process of concrete recycling involves collection, crushing, screening, and grading.

- Consider Crown Dumpster for concrete recycling in Kansas City.

Benefits of Concrete Recycling

Recycling concrete offers a myriad of advantages for the environment, the construction industry, and local communities. By reprocessing old concrete into new material, the need for gravel mining is reduced, resulting in less disruption to wildlife habitats and a decrease in air dust pollution from mining operations.

This practice conserves valuable landfill space, since concrete is a heavy and bulky material. It also significantly cuts down on construction costs by providing a cheaper alternative to fresh aggregate, while simultaneously reducing transportation expenses, as recycled concrete can often be processed and reused on-site.

Furthermore, the energy savings from fewer production and transportation requirements contribute to a reduction in greenhouse gas emissions, aligning with sustainability goals. By choosing to recycle concrete, industries and individuals alike play a part in creating a circular economy, where materials are kept in use for as long as possible, extracting the maximum value before recovery and regeneration.

Finding Local Concrete Recycling Facilities

To locate facilities that recycle concrete near you, start with an online search. Use keywords like “concrete recycling,” “construction material recycling,” or “reclaimed concrete disposal” followed by your city or zip code. This search should yield a list of nearby centers.

Additionally, check with local construction and landscaping supply companies. Many have partnerships with recycling plants and may offer drop-off services or provide you with a direct contact.

Don’t overlook community recycling programs. Some cities have dedicated areas for recycling large materials, including concrete. Contact your municipal waste management department to inquire about these services.

For more comprehensive results, databases such as Earth911 or RecyclerFinder can provide detailed lists of recycling locations. Just input your material type and location for a tailored list of options.

Mobile crushing services are another consideration. These companies come to you to crush concrete on-site, which can be a cost-effective solution for larger projects with substantial amounts of waste material.

Always check the accepted materials and preparation instructions before bringing concrete to a facility, as contamination can hinder the recycling process. Clean concrete, free of rebar and debris, is usually required.

Lastly, ask around in construction-related forums or social media groups. Industry professionals in your area can often recommend reputable recycling centers and may offer additional insights into the most convenient and cost-effective options available.

The Process of Concrete Recycling

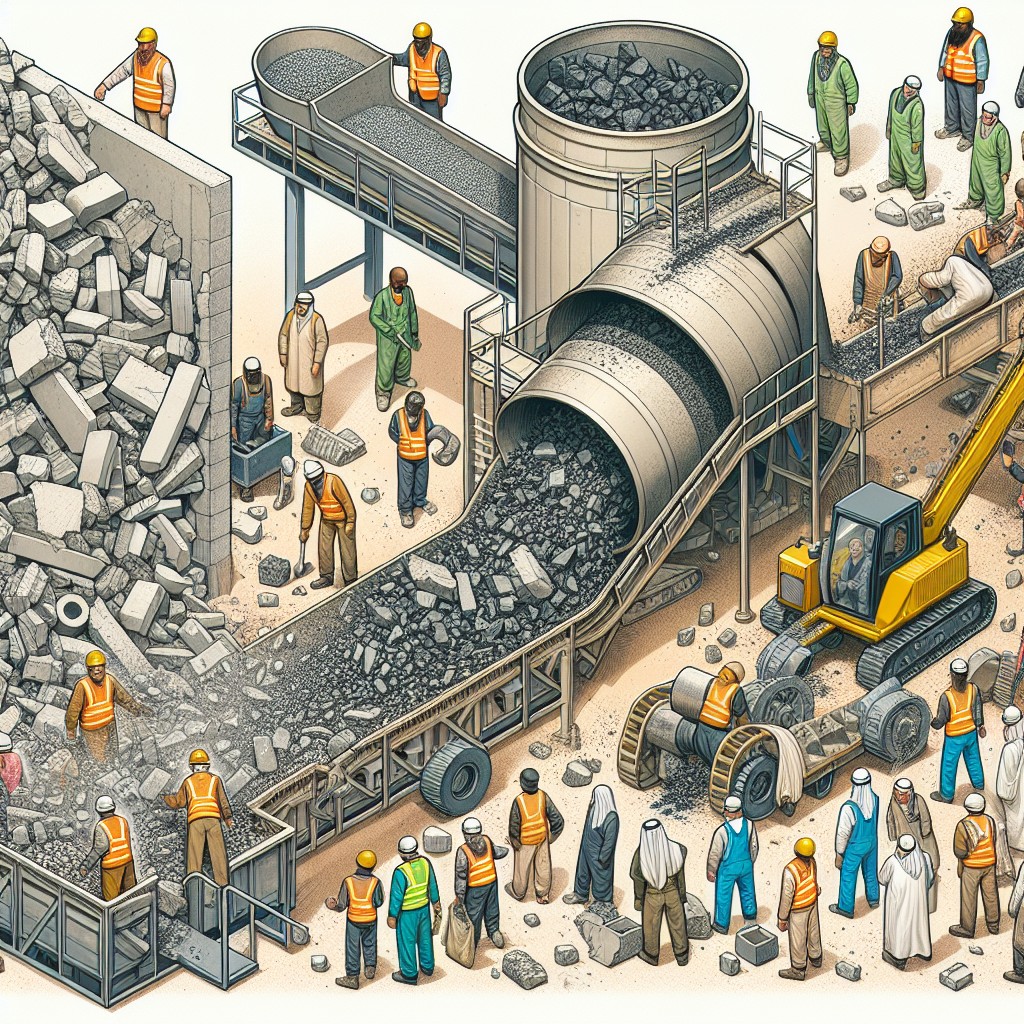

Concrete recycling typically involves several critical steps to convert waste from construction sites, demolition fields, and road refurbishments into reusable material. The core stages include:

- Collection and transport: Discarded concrete is gathered from various sites and transported to the recycling facility.

- Crushing: Special machinery breaks the material down into smaller chunks. This is achieved using jaw crushers, hammer mills, or cone crushers, depending on the processing needs.

- Screening: After crushing, screens of different sizes separate the crushed concrete to ensure uniformity and to filter out unwanted debris.

- Removal of contaminants: Any non-concrete materials like wood, plastic, or metal are removed from the crushed aggregate to purify the final product.

- Size grading: The clean, crushed concrete is sorted into different sizes, which will fit specific future uses, such as sub-base for roads or foundations.

By following these steps, the once-worthless concrete rubble is transformed into a valuable resource, ready to be used in new construction projects, thus promoting sustainability and cost-efficiency.

Choosing Crown Dumpster for Kansas City Concrete Recycling

Opting for Crown Dumpster for your concrete recycling needs in Kansas City offers several advantages. With a reputation for reliability and eco-friendliness, Crown Dumpster ensures that your discarded concrete doesn’t end up in a landfill. Instead, it becomes part of sustainable construction practices.

Here’s why selecting Crown Dumpster is a wise choice:

- Eco-Friendly Solution: They prioritize the environment by diverting waste from landfills and turning it into useful materials.

- Convenient Drop-Off: Their facilities are designed for easy drop-offs, saving you time and hassle.

- Versatile Services: Whether you have a small residential project or a large commercial job, they can cater to different scales of concrete waste.

- Cost Efficiency: By recycling your concrete with Crown Dumpster, you may reduce disposal costs compared to other waste management options.

- Compliance with Regulations: They adhere to local recycling regulations, ensuring that your project complies with necessary environmental standards.

- Support for Local Economy: Using a local service like Crown Dumpster keeps the community’s economy thriving.

Leverage Crown Dumpster’s expertise to manage your concrete debris responsibly and sustainably.

Cost of Concrete Disposal

When considering the disposal of concrete, costs can vary based on several factors:

1. Volume and Weight: The more concrete you have, the more it may cost to dispose of due to the weight. Fees are often calculated based on the weight of the material.

2. Location: Proximity to a recycling facility can impact the cost. Transportation costs increase the farther away you are from the facility.

3. Cleanliness: Costs can be lower if the concrete is free of contaminants. Concrete with rebar or mesh can be more expensive to process.

4. Dumpster Rental: For large projects, renting a dumpster might be necessary. Prices differ depending on the size of the dumpster and rental duration.

5. Facility Fees: Recycling centers typically charge a fee to accept concrete. These fees help cover the costs of crushing and processing the material.

To manage expenses effectively, contact local recyclers for their rates, considering renting a dumpster if handling a large amount of material, and sort your concrete waste to ensure it is free from contaminants.

How Much Concrete Can Be Placed in a Dumpster Rental

Determining the amount of concrete that can be placed in a dumpster rental relies on several factors, including the size of the dumpster, the thickness of the concrete slabs, and local weight restrictions. Here are the key points to consider:

- Dumpster Size: Generally, dumpsters come in various sizes, measured in cubic yards. A typical range for concrete disposal can be 10, 20, 30, or 40 cubic yards. The larger the dumpster, the more concrete it can hold.

Thickness of Concrete: Thicker slabs of concrete weigh more, thus reducing the total volume that can be loaded into the dumpster without exceeding weight limits.

Weight Limits: Dumpster rentals have weight allowances, commonly determined by local regulations and the hauler’s policies. Exceeding these can result in additional fees.

Safety Considerations: Overloading a dumpster not only poses logistical problems but also can be unsafe for transport. Distribute the weight evenly and do not fill the dumpster beyond the rim.

Compliance with Regulations: Ensure compliance with local guidelines to avoid penalties. Some areas have specific rules for disposing of materials like concrete.

For precise guidance, consult with the dumpster rental company to understand the appropriate size needed for your specific concrete disposal project. They can provide valuable advice on how to maximize the use of space while adhering to weight restrictions.

Types of Concrete and Materials to Recycle in Kansas City

Kansas City accepts a variety of materials for concrete recycling. These include:

- Clean concrete: Without paints, excessive metal, trash or hazardous contaminants, this is ideal for recycling.

- Concrete blocks and bricks: Often recovered from building demolitions and can be crushed into aggregates.

- Concrete with rebar: The metal is typically removed with magnets after crushing, though some recyclers may require advance separation.

- Concrete washout: Leftover from construction projects, it can be recycled to avoid contaminating waterways.

Each type of concrete material has potential for a new life through recycling. Keep in mind that the purity of the concrete plays a crucial role in determining its suitability for recycling. Local recycling centers may have specific guidelines; always check their requirements before delivery.

Weight Limits for Concrete Recycling in Kansas City

Understanding the weight restrictions for disposing of concrete is crucial when planning recycling efforts in Kansas City. Here are pivotal points to consider:

– Capacity of Dumpsters: Typically, dumpsters have a weight limit, which can range from 10 to 40 cubic yards, suitable for varying amounts of concrete.

– Tonnage Rates: Facilities often charge by the tonnage. Stay informed about rates to avoid an overspill in your budget.

– Safety Regulations: Weight limits aren’t arbitrary; they adhere to safety standards for transportation and infrastructure protection.

– Overload Fees: Exceeding weight limits can result in additional fees. To prevent this, calculate the weight of concrete before disposal.

– Environmental Impacts: Proper weight management also ensures that trucks efficiently transport waste, minimizing carbon emissions and the ecological footprint of your recycling project.

Always check with your selected recycling facility for their specific guidelines and capacity limits to ensure a seamless concrete recycling process.

Recycled Concrete Aggregates (RCA) Availability

Upon processing, the resulting fragments called Recycled Concrete Aggregates (RCA) find new life in various construction applications. These aggregates typically come in different sizes and quality levels, catering to diverse project requirements. RCA can effectively substitute for traditional gravel or crushed stone in road bases, new concrete, landscaping, or as fill material.

To ensure availability aligns with your project timeline, it’s advisable to check with your local recycling facility well in advance. The supply of RCA may fluctuate based on current demolition projects and the facility’s processing capacity at any given time. Thus, planning is key.

It’s also important to understand the specifications of RCA suitable for your project to guarantee optimal performance. Some considerations include:

- Grade: Facilities often sort RCA by size and cleanliness. Ensure you obtain the grade that matches your structural requirements.

- Volume: Calculate the needed volume, factoring compaction, to ensure an adequate supply.

- Delivery: Discuss onsite delivery options or pickup with the provider to streamline logistics.

By opting for RCA, you’re contributing to reducing landfill waste and promoting sustainable construction practices. It’s a choice that benefits both your project and the environment.

Service Areas for Concrete Recycling

When searching for concrete recycling services, it’s important to consider the range of areas these facilities cover. Ideally, you want a provider that is easily accessible and has a broad service reach.

- Proximity to Major Cities: Look for recycling centers that are close to major urban areas. These centers typically have more extensive hours of operation and resources.

- Accessibility from Construction Sites: Recycling facilities often establish themselves near common construction zones to streamline the transportation and handling of material.

- Rural vs. Urban Services: Understand that services in urban areas might be more regular and accessible, while those in rural areas may require appointments or have specific drop-off times.

- Regional Partnerships: Some facilities may not cover your area but could have partnerships with local transport companies that provide pick-up and delivery services.

- Expansion of Service Areas: As the recycling industry grows, keep informed about new centers opening or existing ones expanding their service radius.

Each facility operates with its own set of rules, so contacting them directly or visiting their website for specific information related to your needs is essential.

Solid Waste Management Department Recycling Facilities

Solid Waste Management Department (SWMD) recycling facilities play a pivotal role in managing the life cycle of concrete materials. These facilities are equipped to handle the segregation, processing, and repurposing of concrete waste, ensuring it re-enters the economic stream without unnecessarily filling landfills.

Segregation Protocols: Upon arrival, concrete rubble is sorted to remove contaminants such as metal, wood, and plastic, which could otherwise hinder the recycling process.

Crushing and Processing: Concrete is then crushed into smaller pieces, often using state-of-the-art machinery, to create recycled concrete aggregates suitable for new construction projects.

Quality Control: Regular testing is conducted to ensure that the recycled aggregates meet the necessary specifications for their intended use.

Environmental Compliance: SWMD facilities adhere strictly to environmental regulations, minimizing the carbon footprint of concrete waste processing.

Resource Recovery: By transforming waste into usable material, SWMD facilities contribute significantly to resource conservation and sustainable building practices.

These key points outline the SWMD facilities’ approach to streamline the transformation of concrete waste into a valuable resource.

Recycled Aggregate Products Offered

Recycled aggregate products offer sustainable alternatives to virgin materials for various construction projects. These products are derived from collected and processed materials that were once part of concrete buildings, bridges, roads, and other structures.

Key offerings typically include:

- Base material for roadways, parking lots, and driveways, which provides a sturdy foundation and promotes drainage.

- Riprap or large-sized chunks used for erosion control to safeguard shorelines, streambeds, bridge abutments, and pilings against water and ice damage.

- Aggregate for new concrete, where it replaces gravel and sand, reducing the demand for quarrying and mining.

- Landscaping material that creates eco-friendly, aesthetically pleasing outdoor designs, helping to conserve natural resources.

- Pipe bedding used for laying underground pipes, offering solid support and preventing damage over time.

These sustainable products not only limit the need to extract new materials but also reduce the environmental footprint associated with construction activities.

Hours of Operation for Local Recycling Centers

Local recycling centers typically operate on a set schedule, which may vary by location. Before planning a visit:

- Verify specific hours online or by calling ahead as they can differ for weekdays, weekends, or holidays.

- Early morning drop-offs are common, but some centers also offer extended hours to accommodate various schedules.

- Seasonal changes can affect operating times, particularly during winter months.

- Check for any special hours for trade professionals or large volume drop-offs which might differ from general public hours.

- It’s wise to arrive well within operating times to ensure you can unload your materials without being rushed.

Guidelines for Acceptable Concrete Rubble

Prior to dropping off your concrete rubble at a recycling facility, ensure it adheres to the required guidelines. Acceptable materials include clean concrete without rebar, uncontaminated concrete blocks, and bricks. Materials not permitted are those containing lead-based paint, large rebar and wire mesh, trash, and excess soil. Small metal fasteners within the concrete are typically acceptable.

Segregate pure concrete from mixed waste to prevent contamination and ensure a smooth recycling process. If necessary, consult with the recycling facility beforehand to clarify what materials they accept and any preparation steps you might need to take. This proactive approach will save you time and help maintain the integrity of the recycled aggregates produced.

Availability of Recycled Aggregate Materials for Purchase

Recycled aggregate materials, stemming from previously utilized concrete, are extensively available for various construction purposes. These eco-friendly alternatives offer several advantages, such as cost savings and a reduced environmental footprint. They are used in projects ranging from road bases to landscape construction.

When purchasing recycled concrete aggregates (RCA), consider the following:

- Grades and Quality: RCA comes in different grades suitable for specific applications. Ensure the quality aligns with your project requirements.

- Volume and Availability: Check with local suppliers to understand the volumes available for immediate or bulk purchase.

- Delivery Options: Suppliers typically offer delivery services. Inquire about delivery costs and scheduling to ensure timely arrival at your site.

- Certifications: Some projects may require certified recycled aggregates meeting particular industry standards.

- Cost Comparison: Evaluate the cost-effectiveness compared to virgin materials; prices can be significantly lower, making it an economical choice.

Local recycling facilities often display the types of recycled aggregate materials they offer, from fine aggregates suitable for pathways to larger, coarse aggregates ideal for structural fills. Contact local suppliers directly for more detailed information on availability and pricing.

To facilitate your concrete recycling efforts, having the right contact information at your fingertips is crucial. Here are some useful points to keep in mind:

- Online Resources: Many concrete recycling services have websites with contact forms to schedule pickups or inquire about services. Look for a “Contact Us” page.

- Local Directories: Check local business directories or online listings for up-to-date phone numbers and email addresses.

- Social Media: Some services may be active on social media platforms where you can direct message them for quick responses.

- Site Visits: If you prefer face-to-face interaction, jot down the physical address of the recycling facility for a walk-in visit during business hours.

- Referrals: Ask for recommendations from local construction professionals who regularly use concrete recycling services.

- Municipal Services: Your city’s waste management department can often provide contact details for sanctioned recycling facilities.

Keep this information handy to streamline your concrete recycling process.

Recap

Liked this article? Here’s what you can read next:

[ad_2]

Source link